Machining and quality assurance

Your innovative full-service provider in the machining of plastics and metals using state-of-the-art production technologies.

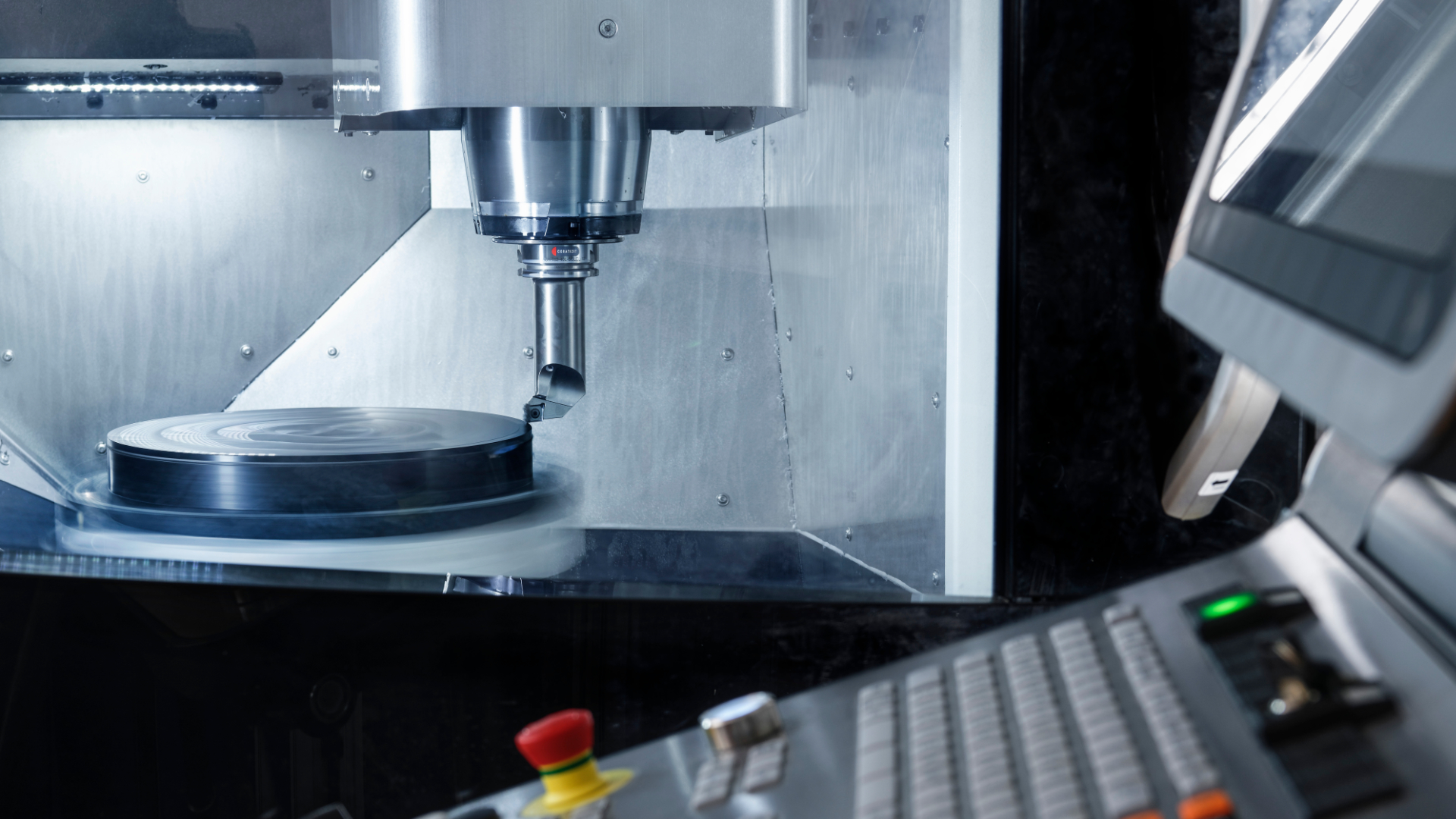

Machining production of plastic and metal parts

Machining to produce your molded parts is carried out on state-of-the-art CNC machines according to your drawings and specifications.

Experienced and highly trained employees are committed to the timely and high-quality fulfillment of your orders. From quotation and order processing through production, surface finishing and cleaning to delivery.

Continuous investment in the latest equipment, production technologies and training forms the basis of our ongoing development and successful growth. The means of production are constantly adapted to market requirements and the state of technology so that we can continue to meet your needs economically tomorrow.

Large and flexible machine park

Competence Center Villmergen

Key data

- 100 employees

- 3’800m2 production area

- 1-3 shift operation

- ISO 13485, EN 9100, ISO 9001, ISO 14001

Strengths

- Processing of plastic

- Long turning in plastic & brass

- Milling of metal and plastic in separate areas

- Milling in the cooling cell of high-precision parts for the semiconductor industry

- Assembly of components for the semiconductor industry

Type of machine / technology

Milling 5 axes incl. rotary table

Dimension:

ø 500

Number of machines:

3

Milling 5 axes

Dimension:

300 x 300

Number of machines:

5

Dimension:

120 x 120

Number of machines:

3

Milling 3 axes

Dimension:

600 x 400

Number of machines:

4

Long turning

Dimension:

bis ø 32

Number of machines:

17

Turning

Dimension:

bis ø 300

Number of machines:

5

Water jet cutting

Dimension:

2000 x 3000

Number of machines:

1

Prototype store

Your partner for the production of high-quality prototype parts in Villmergen

- Personalised advice

- Customised and creative solutions

- Flexible, fast and precise processing

- Fast prototypes with 3D printing or the water jet cutting system

Type of machine / technology

3D printers

Dimension:

290 x 220 x 300

Number of machines:

3

Milling 5 axes

Dimension:

ø 400

Number of machines:

1

Milling 3 axes

Dimension:

500 x 400

Number of machines:

2

Turning

Dimension:

bis ø 250

Number of machines:

2

Competence Center ValMez

Key data

- 100 employees

- 2’700m2 production area

- 1-3 shift operation

- ISO 9001, ISO 13485

Strengths

- Assembly

- Turning of aluminum

- 5-axis machining also for medium and large parts

- Plate processing with router

- Plastic welding

Type of machine / technology

Milling 5 axes

Dimension:

1000 x 800

Number of machines:

2

Dimension:

400 x 400

Number of machines:

7

Mill-turn center

Dimension:

ø 700

Number of machines:

1

Milling 4 axes

Dimension:

500 x 500

Number of machines:

5

Milling 3 axes

Dimension:

800 x 600

Number of machines:

7

Router mill

Dimension:

1500 x 800

Number of machines:

1

Complex turning

Dimension:

ø 200

Number of machines:

8

Easy turning

Dimension:

ø 300

Number of machines:

5

Decoltage

Dimension:

ø 10

Number of machines:

13

Competence Center Worben

Key data

- 30 employees

- 900m2 production area

- 1-3 shift operation

- ISO 13485

Strengths

- Machining from bar stock (milling and turning)

- Titanium and stainless materials

- Medicine in the metal sector

Type of machine / technology

Mill-turn center

Dimension:

ø 42

Number of machines:

3

Long turning

Dimension:

ø 700

Number of machines:

14

Turning

Dimension:

bis ø 42

Number of machines:

1

Tested and documented quality

Complex and high-precision finished parts place high demands on testing processes and testing equipment. Qualified employees and the monitoring and regular calibration of measuring equipment form the basis for meeting these requirements. The test results from the production processes are recorded in appropriate documentation. In addition to a wide range of different test equipment, 3D measuring machines are also used in an air-conditioned environment.