Production of medical devices according to today's standards

Medical products

Instruments and implants are our passion. Screwdrivers or assemblies for endoscopy, implants for osteosynthesis, the spine or dental applications, ports for repeated drug administration or dialysis – as soon as we know the function of the assembly, we align the quality processes with the requirements and shape your product from plastics such as PEEK, POM, PPSU, PE-UHMW or stainless steels and titanium. Electropolishing, passivating, anodizing, marking, cleaning, sterile packaging and much more are all part of our repertoire.

Instruments and implants

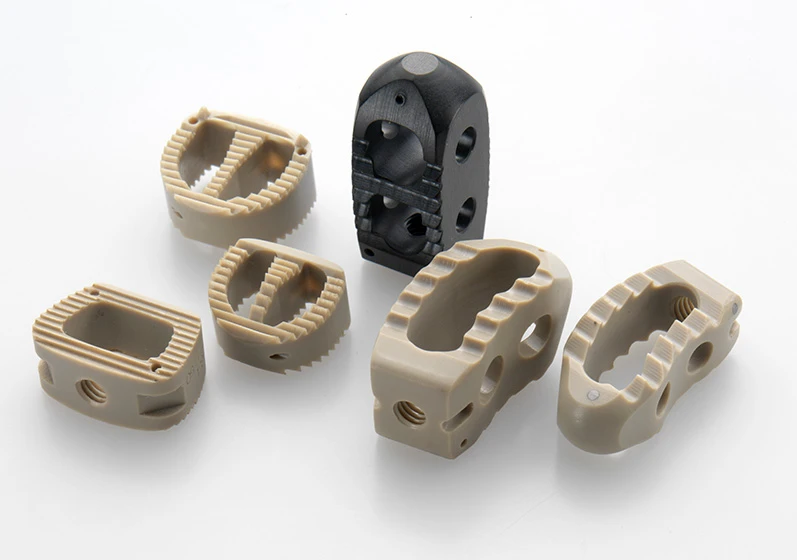

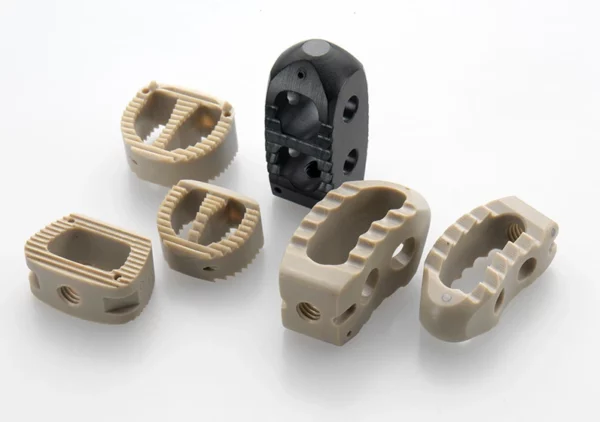

Inserts

Depending on the application or operation process/system, both plastics and metals are used for inserts. If metals are used, then suitable stainless steels are applied. Following production, the parts run through a range of surface treatments to achieve the ideal finish.

Handles

For medical equipment.

Implants

Spinal implants made from PEEK are processed dry to minimise the risk of contamination. X-ray transparent implants contain tantalum markers for monitoring their position.

Spot film devices

Spot film devices are usually used when inserting bone plates. These spot film devices are high-precision instruments that require a maximum degree of accuracy, strength and stability, particularly because they are used multiple times and therefore require repeat sterilisation (and as a result are frequently subject to high temperatures). Further criteria include biocompatibility, X-ray transparency and easy handling for the surgeon. In the majority of cases, a material consisting of PEEK and a carbon fibre mesh is used for these devices.